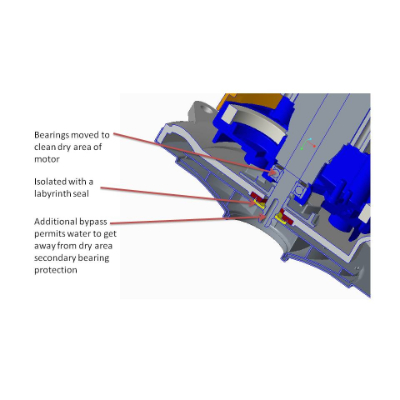

Wet Bearing Protection

Wet bearing protection in selected vacuum motors prevents grease washout of working end bearings in wet applications. Ametek's enhanced bearing seal increases the life of motors by moving the bearing away from the moisture-prone fan system.