Uses

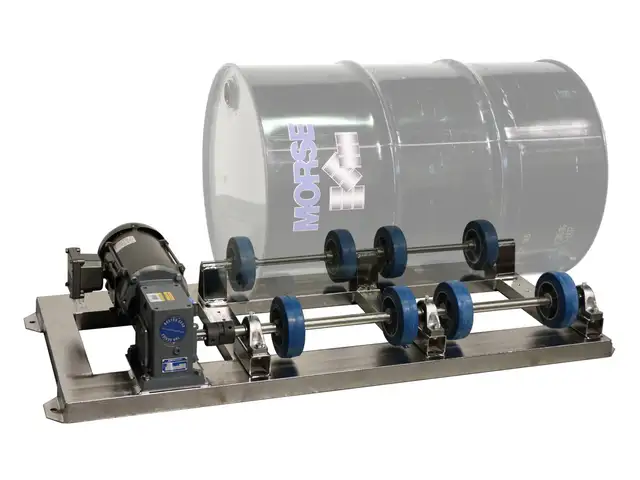

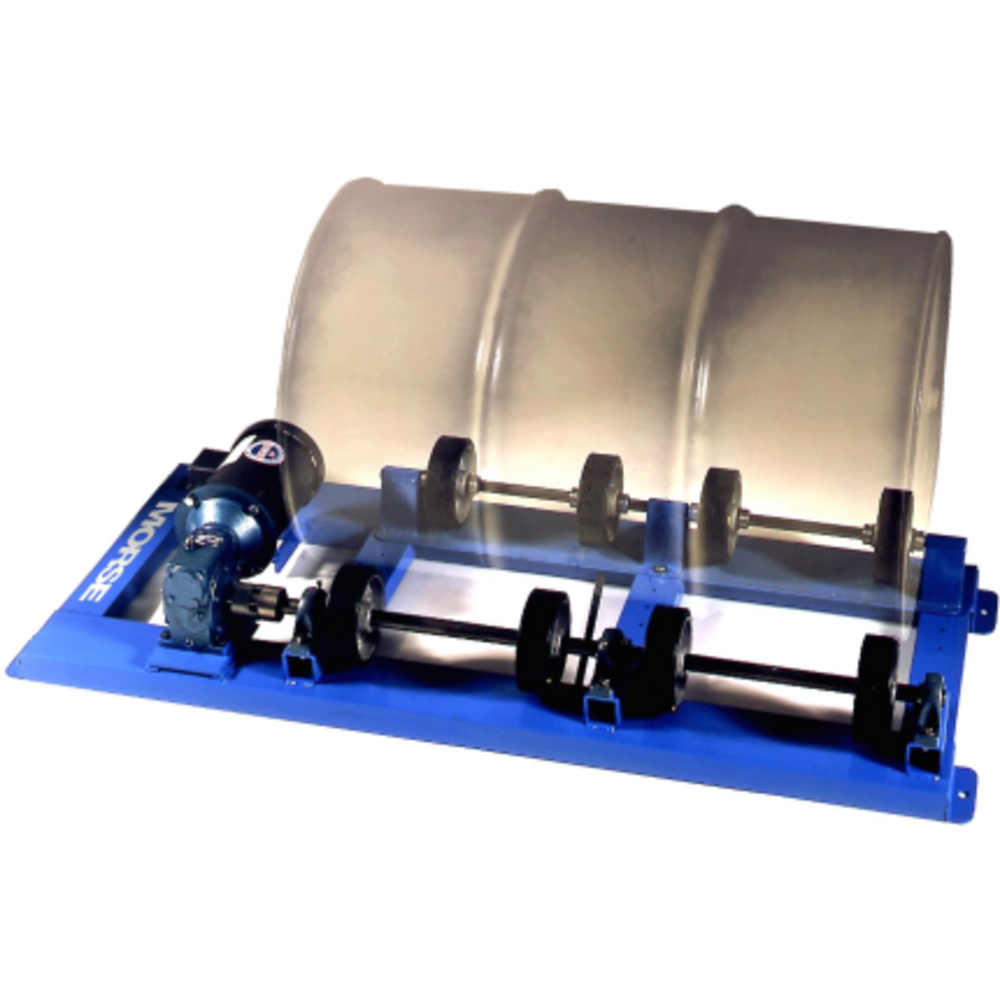

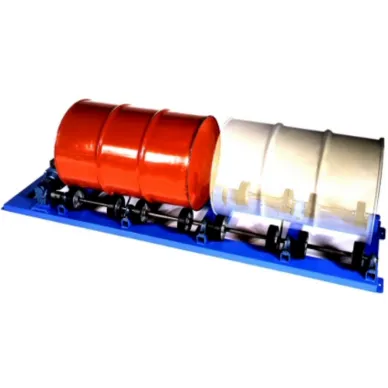

Drum rollers are ideal for homogenising content inside the drums by mixing stratified sediments from the bottom. These Morse drum rollers are suitable for use in petroleum, oil, paint, brewery and food processing industries. Selected drum rollers are strong enough to be hauled around from one area to another without causing any leakage.

Standards and Approvals

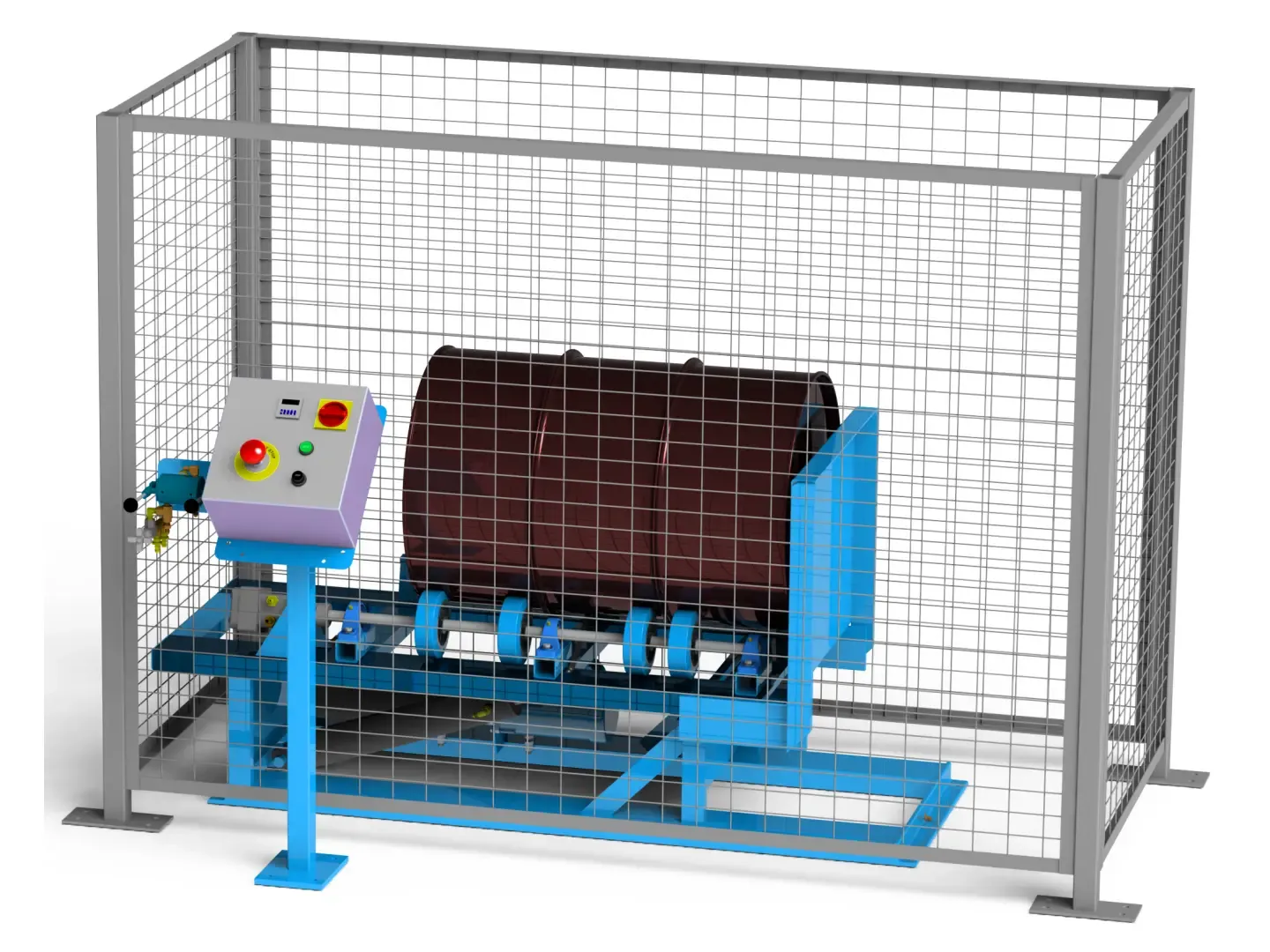

For a safe & secure operation, drum rollers should be installed in accordance with OSHA subpart O.1910.212 "General requirements for all machines" and O.1910.212(a)(4) standards that states "Barrels, containers, and drums. Revolving drums, barrels, and containers shall be further guarded by an enclosure that is interlocked with the drive mechanism.

Frequently Asked Questions

What are some safety tips that one needs to remember while operating the drum rollers?

Users should pay attention to the following safety instructions while operating the drum rollers:

How to handle chemical drums?

Drum rollers are ideal for handling drums containing chemicals prone to spillage. These units ensure user safety against chemical burns by using a remote control mechanism.

What is the difference between a Morse drum roller and a Morse drum tumbler?

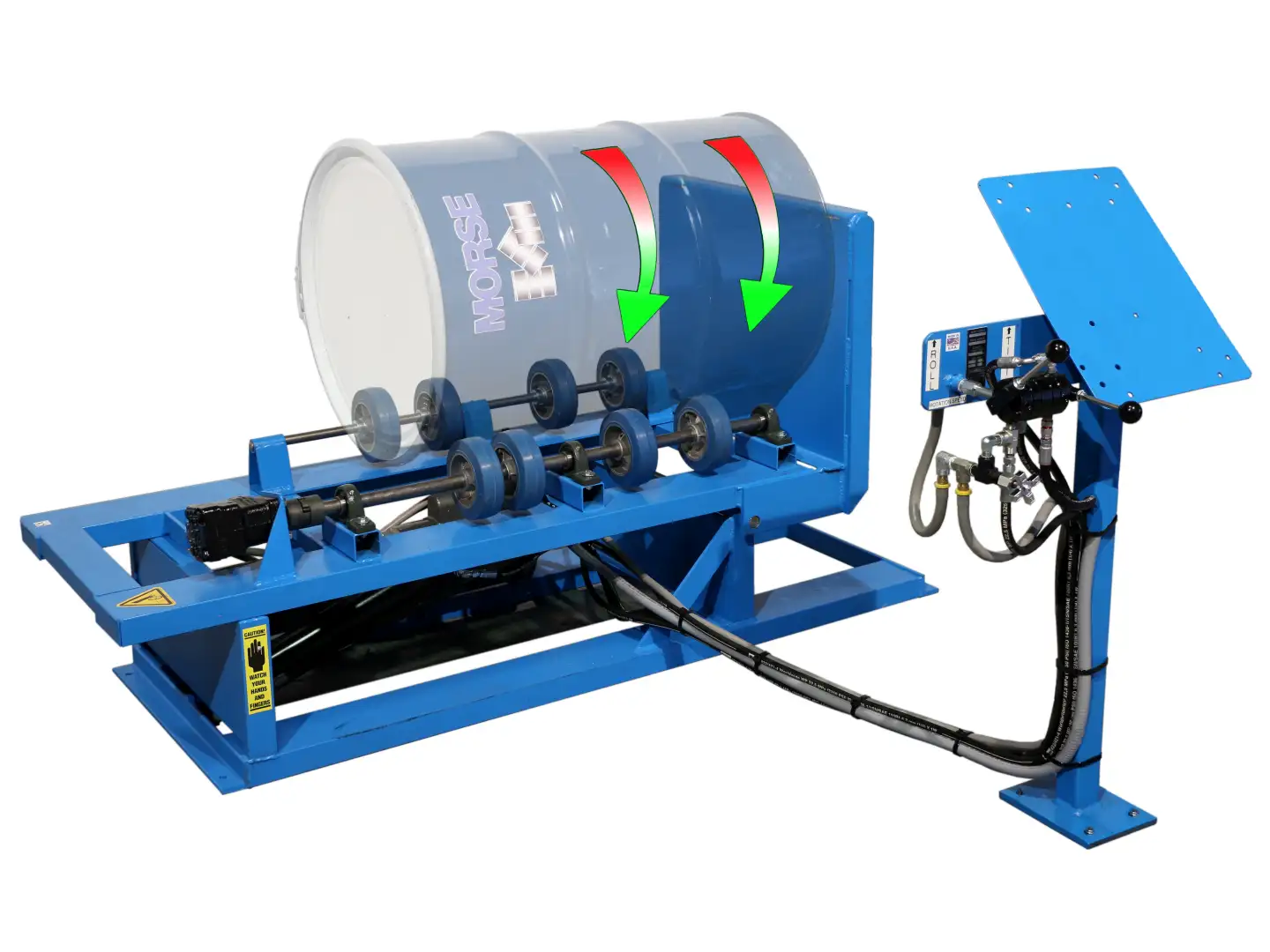

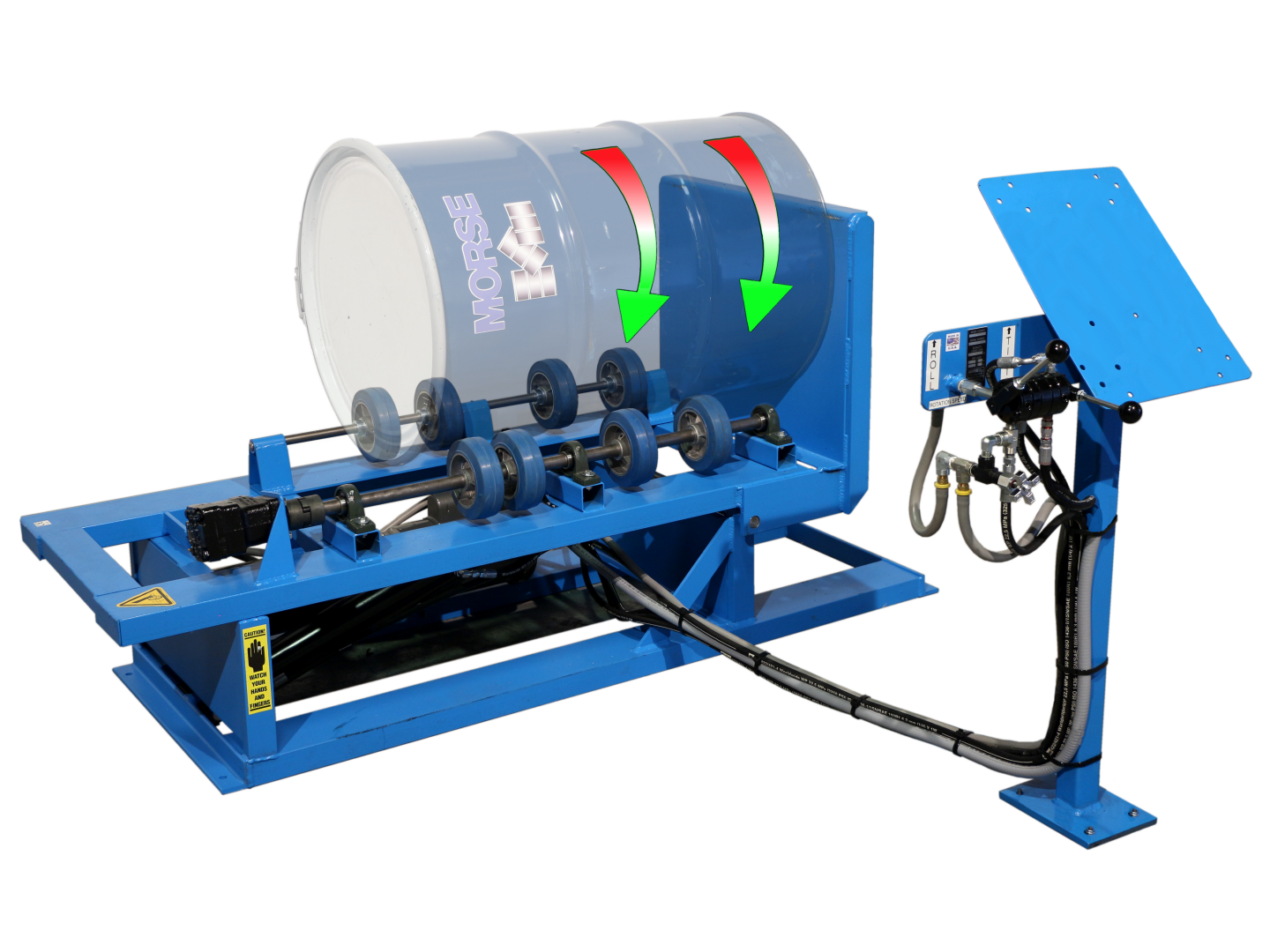

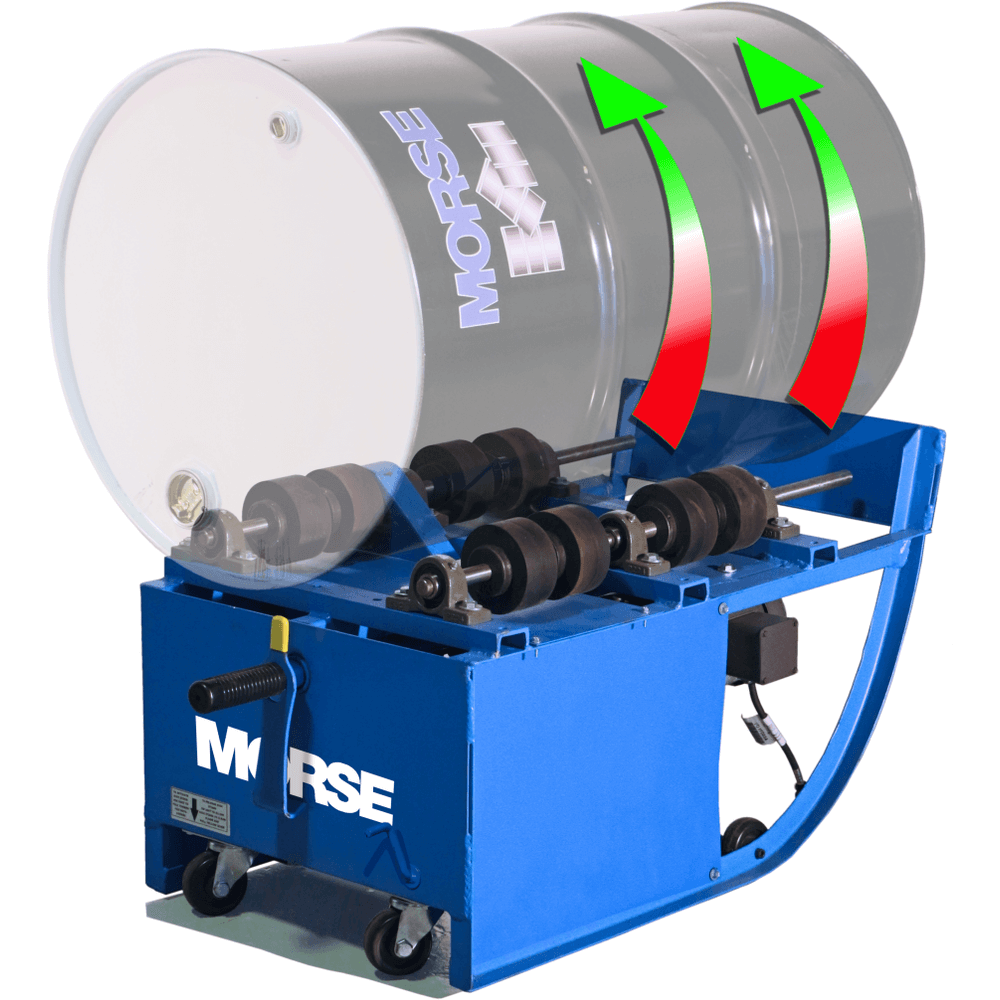

Drum tumblers are used to vigorously mix drum content, usually viscous or easy-settling fluids, coarse pellets, wet grains or powder. These units feature heavy stationary feet and, therefore, require moving of the drums for mixing. Drum rollers, on the other hand, are lightweight and mix the content more safely by holding the drums in place and turning them on rollers. These drum rollers are easily movable and can be transported to the exact mixing location.

Which Morse drum roller should I buy?

You can select a roller based on the drum you'll be using. Also, consider the integration of either fixed or variable speed rollers, depending upon what kind of mixture you're dealing with. Buyers should also note if they require in-situ operation for mixing contents at the same place as the drums (use portable drum rollers) or want to have a dedicated drum mixing location (use stationary drum mixers). Hydra-Lift drum mixers are ideal for applications where drum lifters and other equipment can not be used.

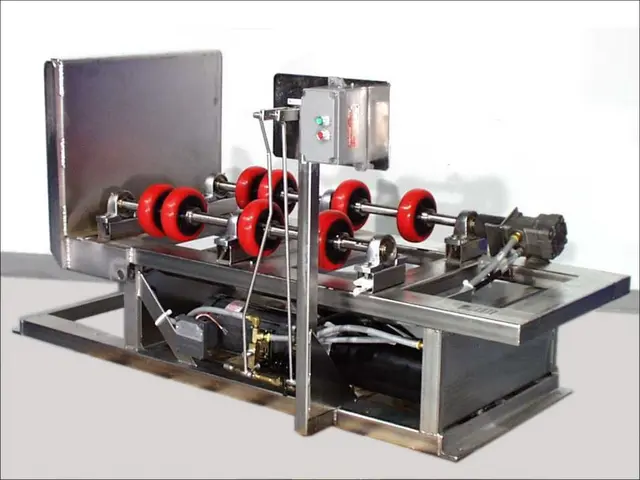

What accessories are compatible with Morse drum rollers?

Raptor Supplies offers a wide range of safety accessories like guard enclosure kits & control packages for quick, easy & safe operation. The guard enclosure kits, with a safety interlock facility, are used to switch off the drum rollers when anyone opens the gate.

How can I transport a drum roller to a job site?

Drum rollers are heavy equipment and usually require a specialised trailer or lowboy truck for transportation. Ensure that the transportation vehicle is properly rated for the weight of the roller and that all necessary permits and safety measures are in place.

How does a vibratory drum roller work?

Vibratory drum rollers have an eccentric weight system that causes the drum to vibrate rapidly. This vibration helps to compact materials efficiently by settling particles closer together.

When should I use a static drum roller?

Static drum rollers are used for finishing and smoothing surfaces after initial compaction with a vibratory roller. They are effective for achieving a smooth, even surface on asphalt and other materials.

How do I determine the compaction rate of a drum roller?

Compaction rate depends on the roller's weight, drum type (vibratory or static), drum size and the material being compacted.

What is the difference between smooth drum rollers and padfoot drum rollers?

Smooth drum rollers have a flat, smooth surface on their drums and are primarily used for asphalt and granular materials. Padfoot drum rollers have protruding, segmented pads on their drums and are more suitable for compacting cohesive soils.

How do a compactor and a drum roller differ from one another?

Although both rollers and compactors are large pieces of equipment used to compact soil, their functions are different. A roller is commonly used to compact soil or asphalt after it has been laid down. A compactor, on the other hand, is used to compact soil before any construction work begins.

£ GBPChange Country

£ GBPChange Country