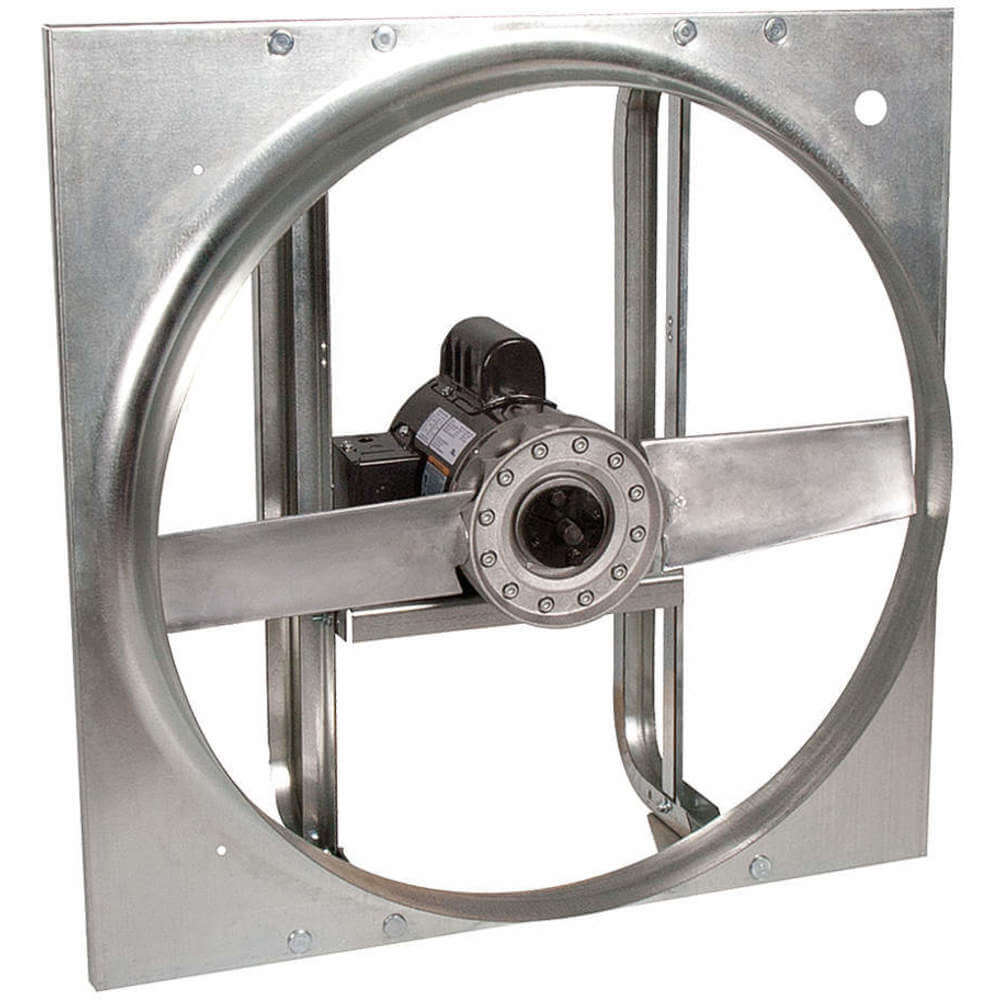

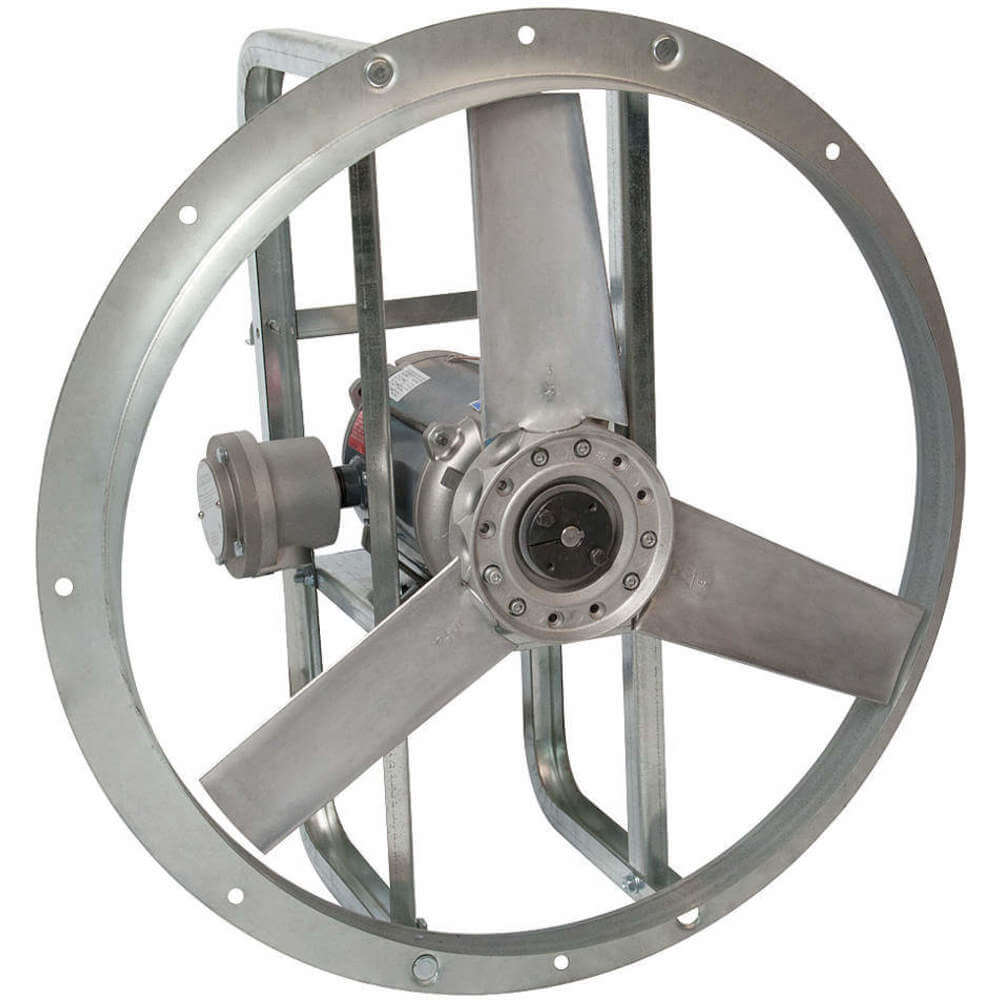

Aluminum Wall Shutter No.: 3C308 , Bearing Type: Ball , Flange Depth: 1-7/8" , Flange Width: 1" , Frame Finish: Galvanized , Frame Material: Galvanized , Hz: 60 , Intake Guard No.: 1WBU3 , Max. Ambient Temp.: 104 F , Motor Enclosure: Explosion Proof Fan Cooled , Motor Insulation: Class B , Mounting Position: Vertical or Horizontal , Propeller Material: Aluminum , Type: Direct Drive, Hazardous Location

Hazardous Location Exhaust Fans, Explosion Proof, 24 Inch

Dayton hazardous location fans remove harmful gases, fumes and flammable vapours from industrial environments. They feature spark-resistant aluminium propellers and 24-inch galvanised frames. These explosion proof fans are equipped with a 60Hz motor (1 or 3 phase) and ball bearings for high rotation speeds. They have Class B insulation and comply with UL, cUL, AMCA and CSA standards. Choose from a wide range of these hazardous location fans, available in ring and panel variants.

Raptor Supplies also offers 20 inch explosion proof fans.

Working Mechanism

- Check the tightness of all the fasteners before turning on the fan.

- Rotate the fan propeller with a hand before starting the fan to ensure smooth rotation.

- Turn on the fan and check for any unusual noise.

- Check for overloading while the motor is in operation.

Features

- Dayton hazardous location exhaust fans have a powerful motor that drives the fan blades to move large volumes of air.

- These 24 inch explosion proof exhaust fans consist of a guard enclosing the fan blades to prevent damages and injuries from accidental contact.

- They feature galvanised steel construction for durability.

- These industrial wall-mounted fans have a totally enclosed motor and spark-resistant aluminium propellers to prevent fire .

- They feature high-performance ball bearings for a long life.

Frequently Asked Questions

How to install these exhaust fans?

- Drill an appropriate-sized hole in the wall.

- Mount the fan on a rigid frame to prevent movement during operation.

- Maintain a 1/4 inch clearance around its perimeter.

- Use fasteners in all pre-punched holes for secure connections.

- Install remaining components like shutter and intake guard.

What are the power requirements of these exhaust fans?

Dayton offers a variety of hazardous location exhaust fans that can run on a single or three-phase power supply.

How do we keep these fans in good working conditions?

- Conduct periodic inspections for cleaning the fan propeller and the housing unit.

- Check for unusual noise while the fan is in operation.

- Check for tightness of the fasteners at regular intervals.

How many blades do these exhaust fans have?

Dayton exhaust fans come in two-blade and three-blade variants.

How much power do these fans produce?

Dayton exhaust fans are equipped with 1/2, 1/3 or 3/4 HP motors for diverse uses.

Change Country

Change Country