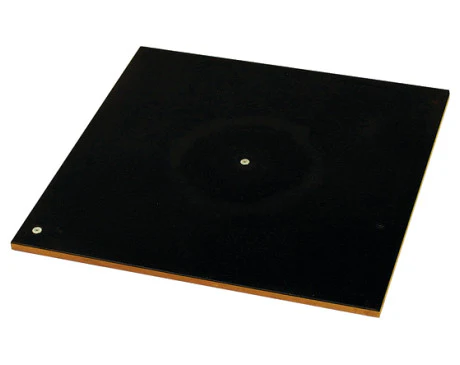

Allpax M3-Rotary Style Gasket Cutters

Designed for cutting accurate ring, flange and irregular shape gaskets. Suitable to cut non metallic gasket materials (rubber, cork & fibre) of up to 1/4 inch thickness. Crank operated cutting mechanism for flexibility & speed control over gasket cutting. Accessory scale bars for extending the cutti...