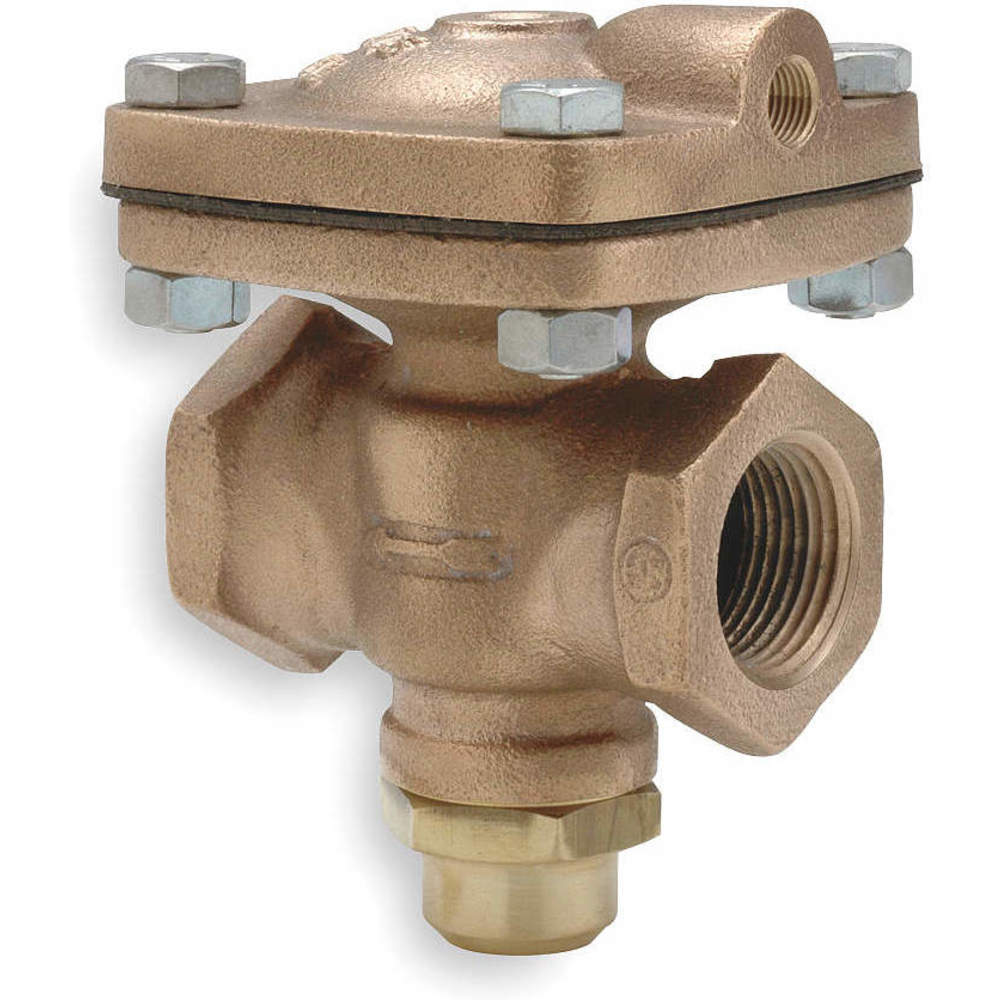

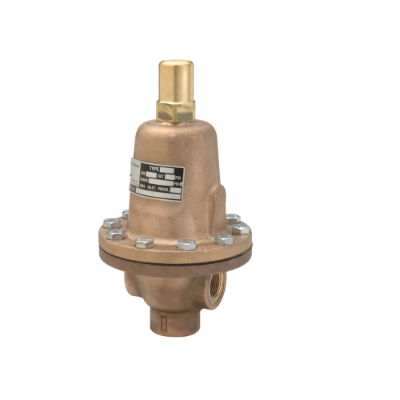

KP Series Back Pressure Valves

These pilot-operated back pressure valves provide dependable protection and accurate control against overpressure conditions. They feature brass construction, stainless steel spring and Buna-N seat disc & diaphragm, allowing pressure setting from 15 to 200 psi.