| A | 3 782 SS-N flanged end | - | FNPT | Cast Stainless Steel | 285 @ 100 Degrees F For WOG, 150 @ 565 Degrees F For Steam | 0.062" | 3" | £3,095.93 | |

| A | 4 782SS -N | - | FNPT | Cast Stainless Steel | 285 @ 100 Degrees F For WOG, 150 @ 565 Degrees F For Steam | 0.062" | 4mm | £5,056.08 | |

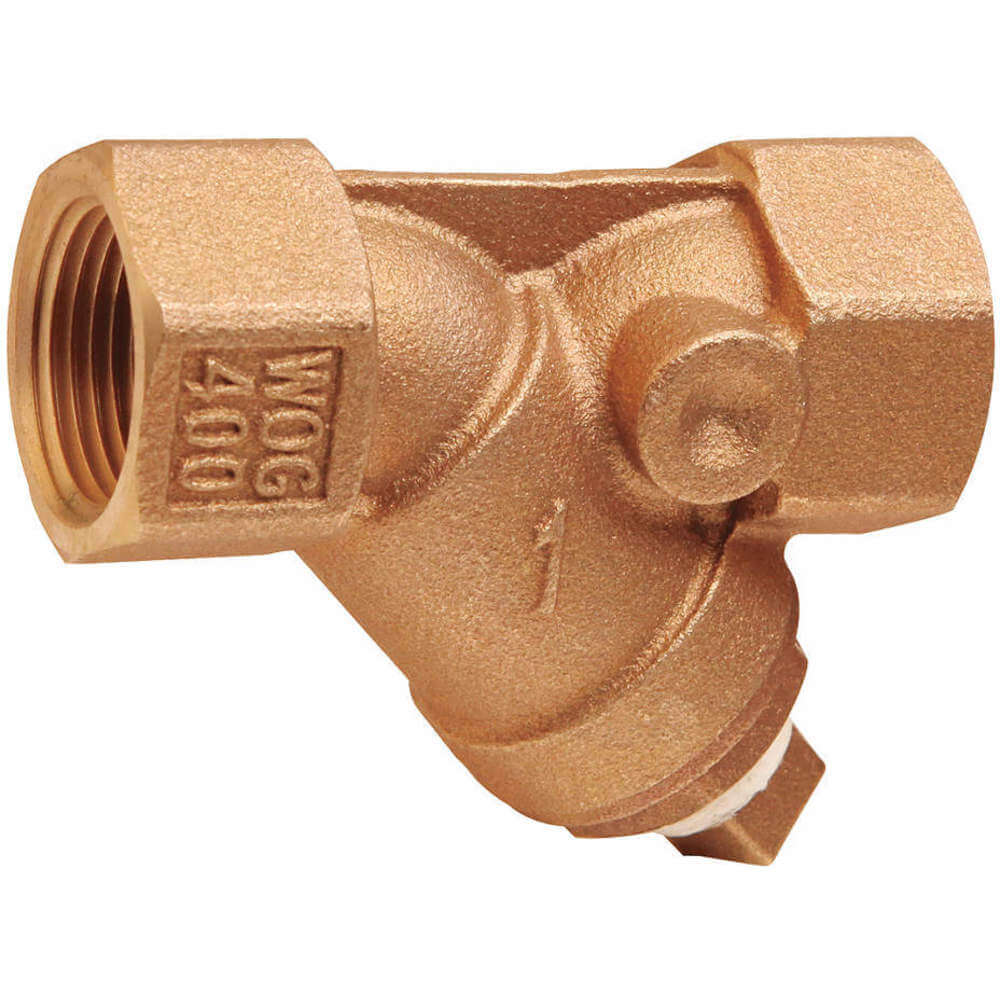

| B | 4 758 N | - | FNPT | Cast Iron | 200 @ 150 Degrees F For WOG, 125 @ 450 Degrees F For Steam | 0.062" | 4mm | £615.20 | |

| A | 21/2 782 SS-N flanged ends | - | FNPT | Cast Stainless Steel | 285 @ 100 Degrees F For WOG, 150 @ 565 Degrees F For Steam | 0.062" | 2.5" | £2,431.11 | |

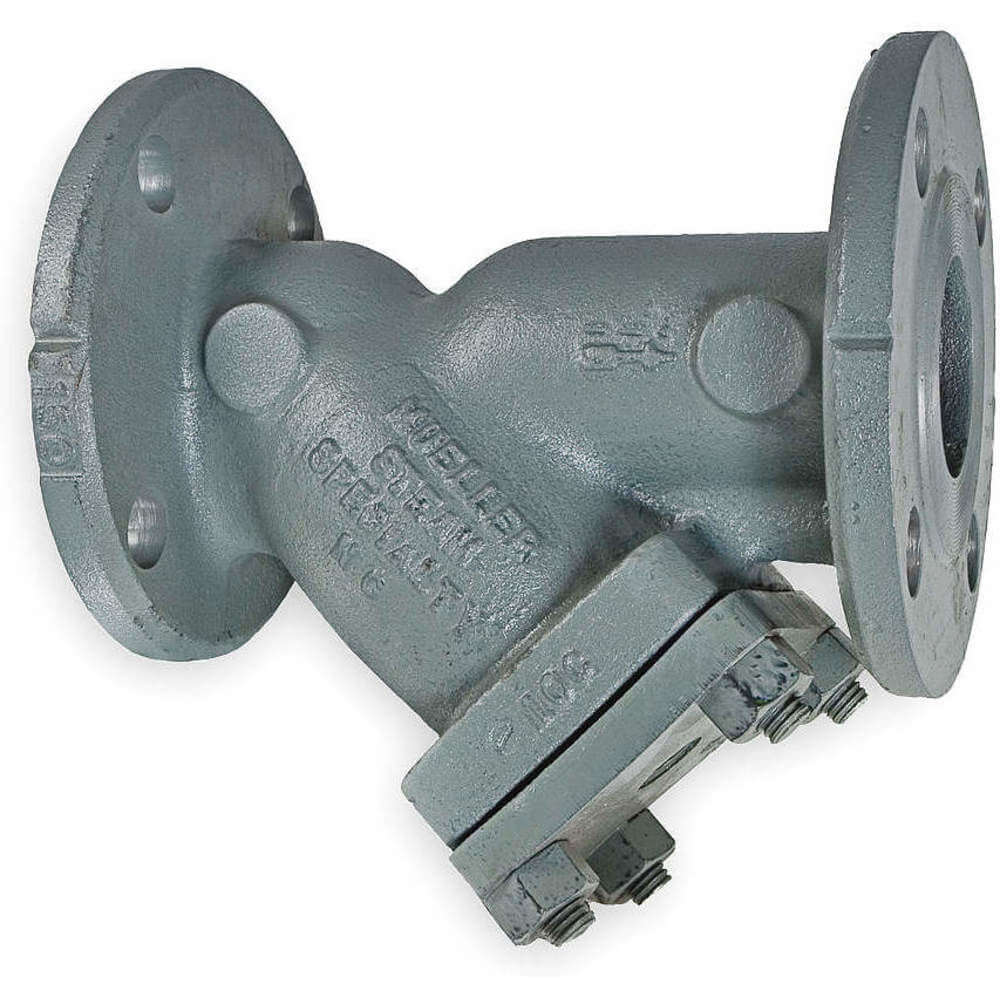

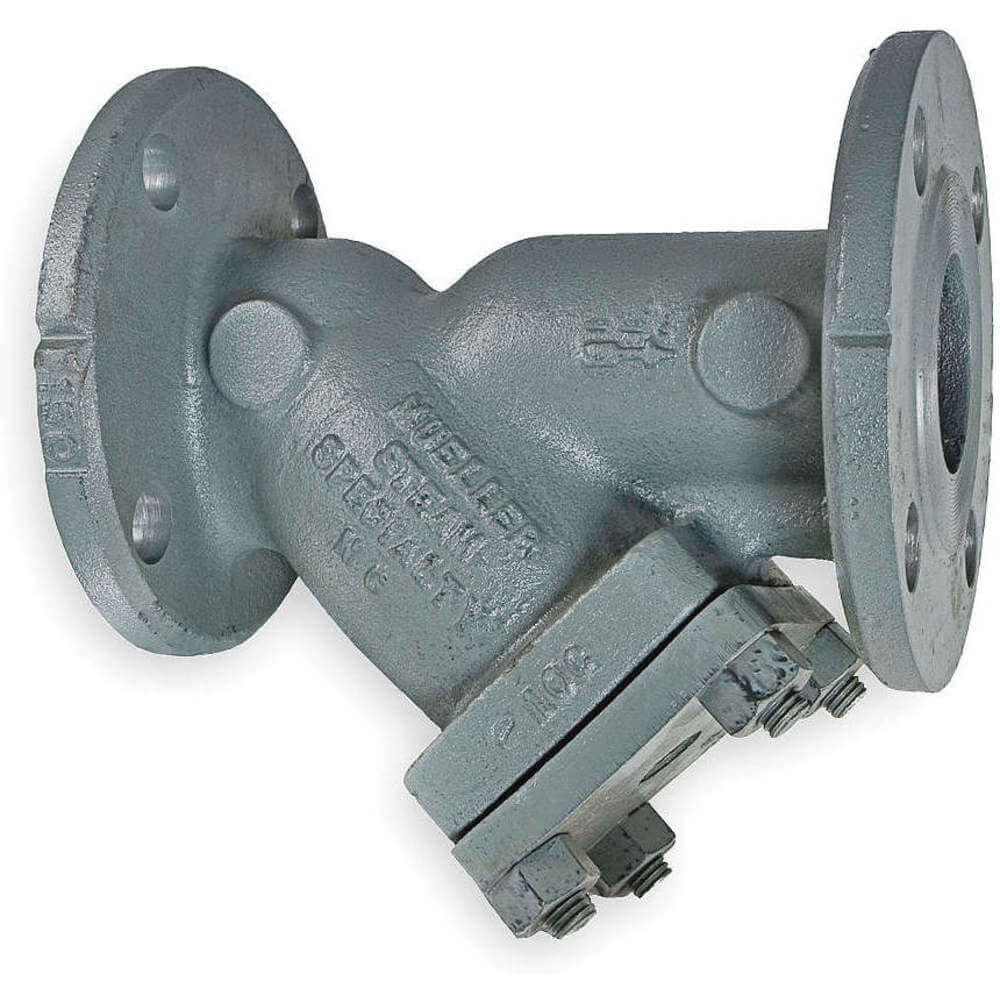

| B | 21/2 758N Iron Body flanged | 125 | FNPT | Cast Iron | 200 @ 150 Degrees F For WOG, 125 @ 450 Degrees F For Steam | 0.062" | 2.5" | £257.78 | |

| B | 3 758 N Iron Body | 125 | FNPT | Cast Iron | 200 @ 150 Degrees F For WOG, 125 @ 450 Degrees F For Steam | 0.062" | 3" | £348.60 | |

| A | 4 781 SS- N flanged | 150 | Flanged | Cast Stainless Steel | 285 @ 100 Degrees F For WOG, 150 @ 565 Degrees F For Steam | 0.062" | 4mm | £3,738.61 | |

| C | 4 781 CS-N flanged end | 150 | Flanged | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 4mm | £1,823.71 | |

| C | 3 781 CS-N flanged ends | 150 | Flanged | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 3" | £1,265.68 | |

| A | 3 781 SS-N flanged | 150 | Flanged | Cast Stainless Steel | 285 @ 100 Degrees F For WOG, 150 @ 565 Degrees F For Steam | 0.062" | 3" | £2,498.69 | |

| D | 3 752 Iron body flanged | 250 | Class 250 Flange | Cast Iron | 500 @ 150 Degrees F For WOG, 250 @ 450 Degrees F For Steam | 0.062" | 3" | £663.72 | |

| D | 4 752 iron body flanged | 250 | Class 250 Flange | Cast Iron | 500 @ 150 Degrees F For WOG, 250 @ 450 Degrees F For Steam | 0.062" | 4mm | £1,198.66 | |

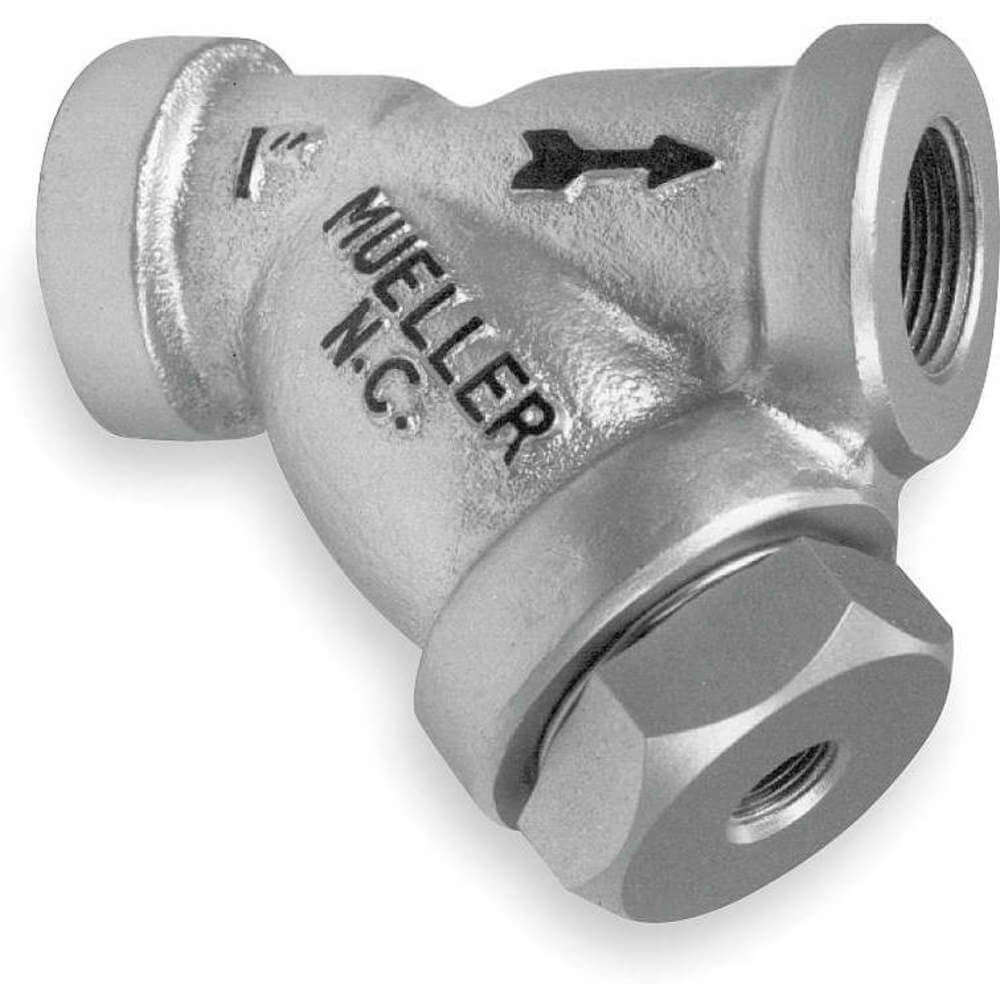

| E | 1 581 CS Screwed ends | 600 | FNPT | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 1" | £285.02 | |

| E | 1/2 581 CS screwed end | 600 | FNPT | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 1/2" | £111.54 | |

| E | 11/2 581 CS screwed end | 600 | FNPT | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 1.5" | £286.34 | |

| F | 1 582 CS socket weld | 600 | Socket Weld | Cast Carbon Steel | 1480 At 100 Deg F For WOG, 1010 At 750 Deg F For Steam | 1/16" | 1" | £169.69 | |

| G | 11/4 581 SS screwed end | 600 | FNPT | Cast Stainless Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 1.25" | £568.94 | |

| E | 3/8 581 CS Screwed end | 600 | FNPT | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 3/8" | £301.23 | |

| E | 11/4 581 CS srewed end | 600 | FNPT | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 1.25" | £233.23 | |

| F | 11/4 582 CS socket weld | 600 | Socket Weld | Cast Carbon Steel | 1480 At 100 Deg F For WOG, 1010 At 750 Deg F For Steam | 1/16" | 1.25" | £246.90 | |

| G | 1 581 SS screwed end | 600 | FNPT | Cast Stainless Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 1" | £446.36 | |

| G | 1/2 581-SS screwed end | 600 | FNPT | Cast Stainless Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 1/2" | £284.15 | |

| E | 2 581 CS screwed end | 600 | FNPT | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 2" | £338.17 | |

| F | 3/8 582 CS socket weld | 600 | Socket Weld | Cast Carbon Steel | 1480 At 100 Deg F For WOG, 1010 At 750 Deg F For Steam | 1/16" | 3/8" | £9,445.06 | |

| E | 1/4 581CS Screwed ends | 600 | FNPT | Cast Carbon Steel | 1480 @ 100 Degrees F For WOG, 1010 @ 750 Degrees F For Steam | 1/16" | 1/4" | £279.68 | |

£ GBPChange Country

£ GBPChange Country