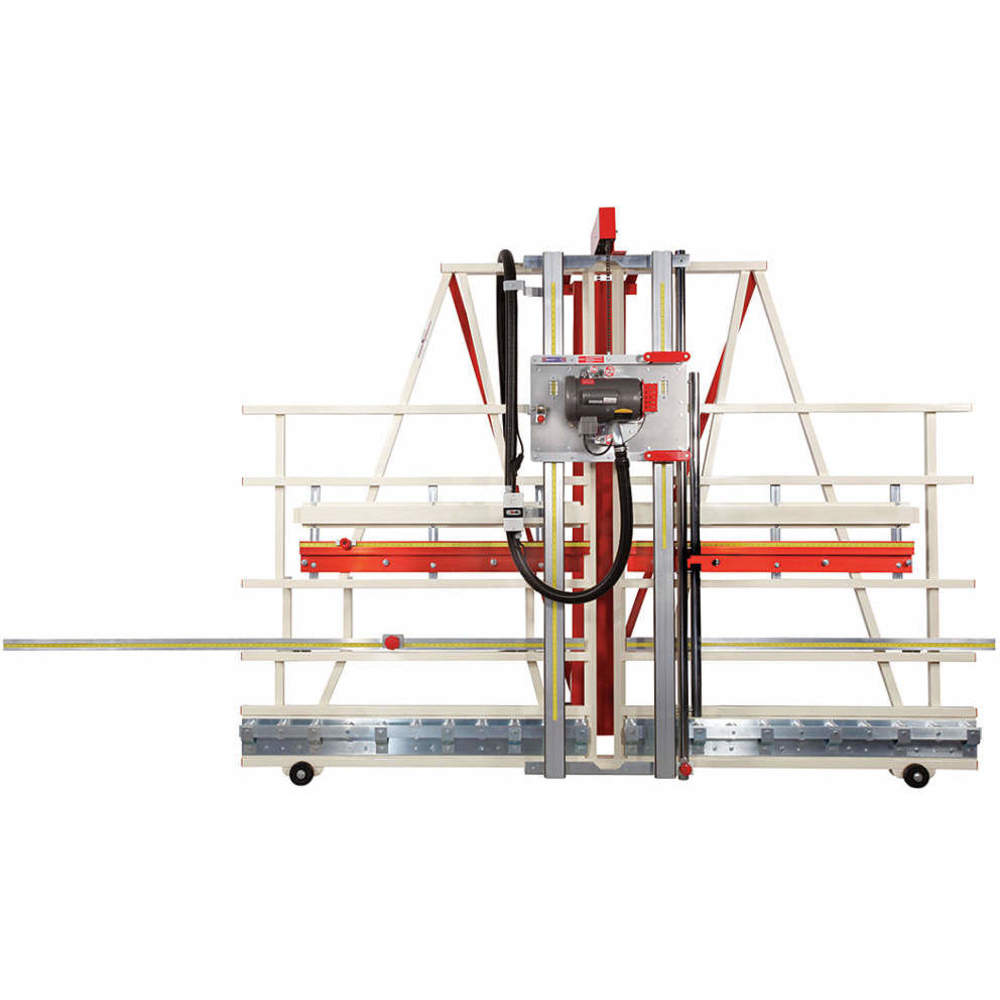

C4 Panel Saws

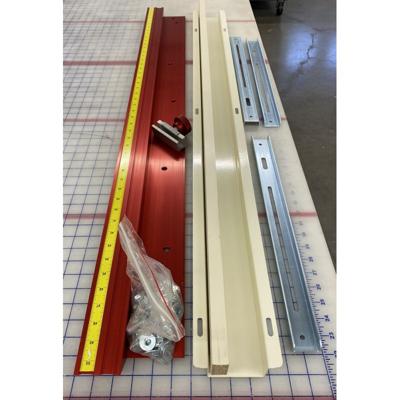

These portable frame saws are designed for the accurate and efficient cutting of large sheets of wood, plastic and other materials. They can create maximum 55 inches crosscuts by using adjustable vertical and horizontal rulers. They feature a 4 Nylatron roller bearing system for smooth performance, ...