Uses

These bench grinders offer a wide combination of features, making them useful for shaping, fabricating, grinding and sharpening cutting tools, wood, chisels, gouges, tool bits, drill bits, tips & sheets in the engineering, electrical, automotive, aerospace and construction industries. They can also be used for grinding, deburring, chamfering and cleaning applications.

Features

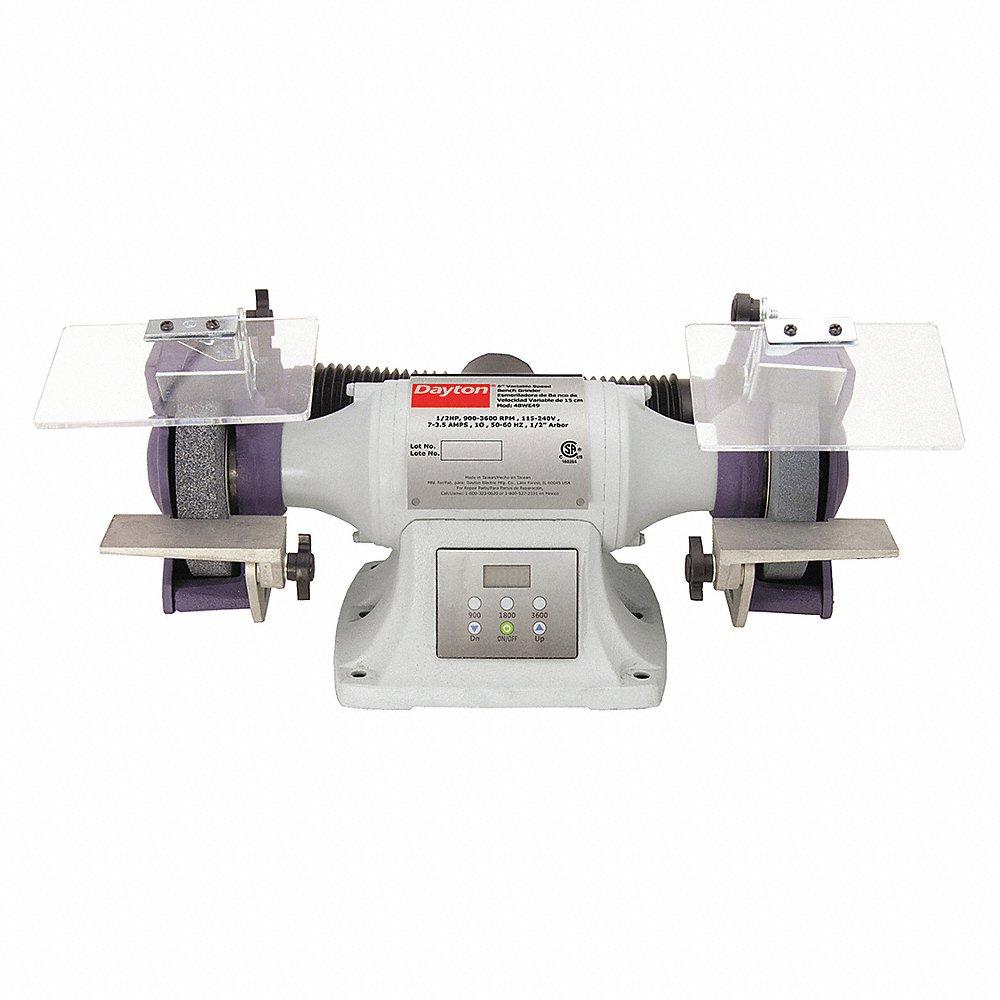

Dayton Bench Grinders

- Dayton bench grinders are equipped with high quality motors for long duty cycle and heavy duty use on carbon metals and alloys.

- These grinders provide extended wheel to wheel clearance that allows long items to be grounded easily and have large adjustable tools which rest for angular grinding, as well as secure & efficient tilt.

- Dayton bench grinders come equipped with sealed bearings and dynamically balanced rotors to minimise vibration for smooth operation.

- They also come with ball bearings for low rotational friction and deliver a maximum wheel speed of 3450 rpm.

- These bench grinders provide approximately 4 to 7 times longer duty cycles under loading condition and deliver 8 times less speed than most conventional bench grinders.

- Dayton bench grinder also feature spark guards and adjustable safety eye shields that are attached with hurricane bolts for additional safety.

Fervi Bench Grinders

- Fervi bench grinders are industrial power tools ideal for detaching or cutting materials.

- They come with a grinding wheel to perform coarse grinding of materials and a brush for cleaning the residue thereafter.

- These units have brackets for supporting pieces and suction holes (placed in rear parts of the guard), along with 4 bolts, to enable secure & easy installation on a workbench.

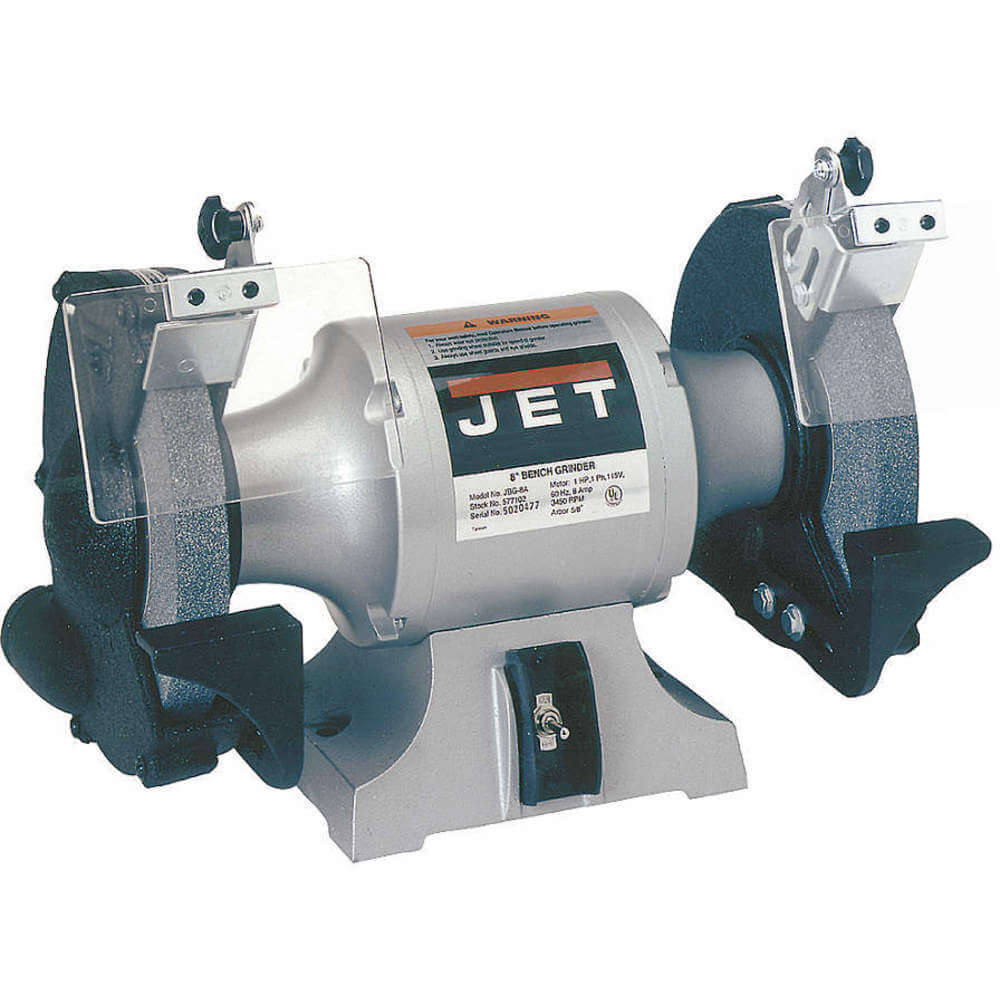

Jet Tools Bench Grinders

- Jet Tools industrial bench grinders offer variable grinding, with fine (60 grit) and coarse (36 grit) transparent grinding wheels.

- These bench grinders feature completely enclosed, pre lubricated ball bearings and rubber mount to avoid movement during vibration of the machine.

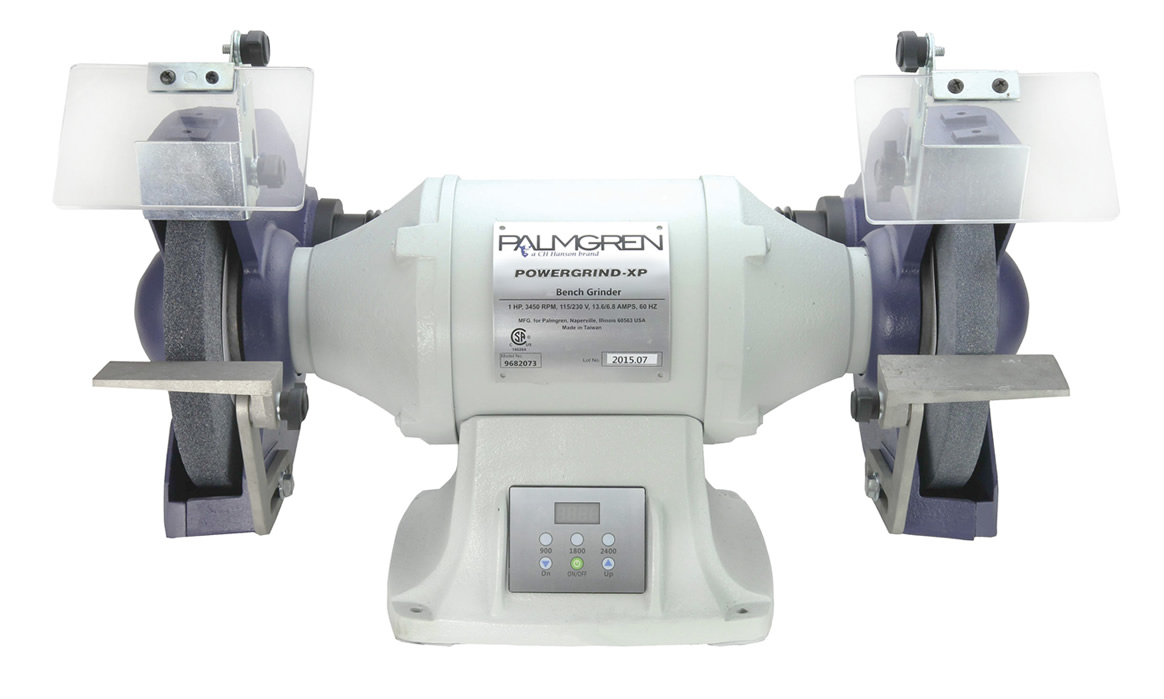

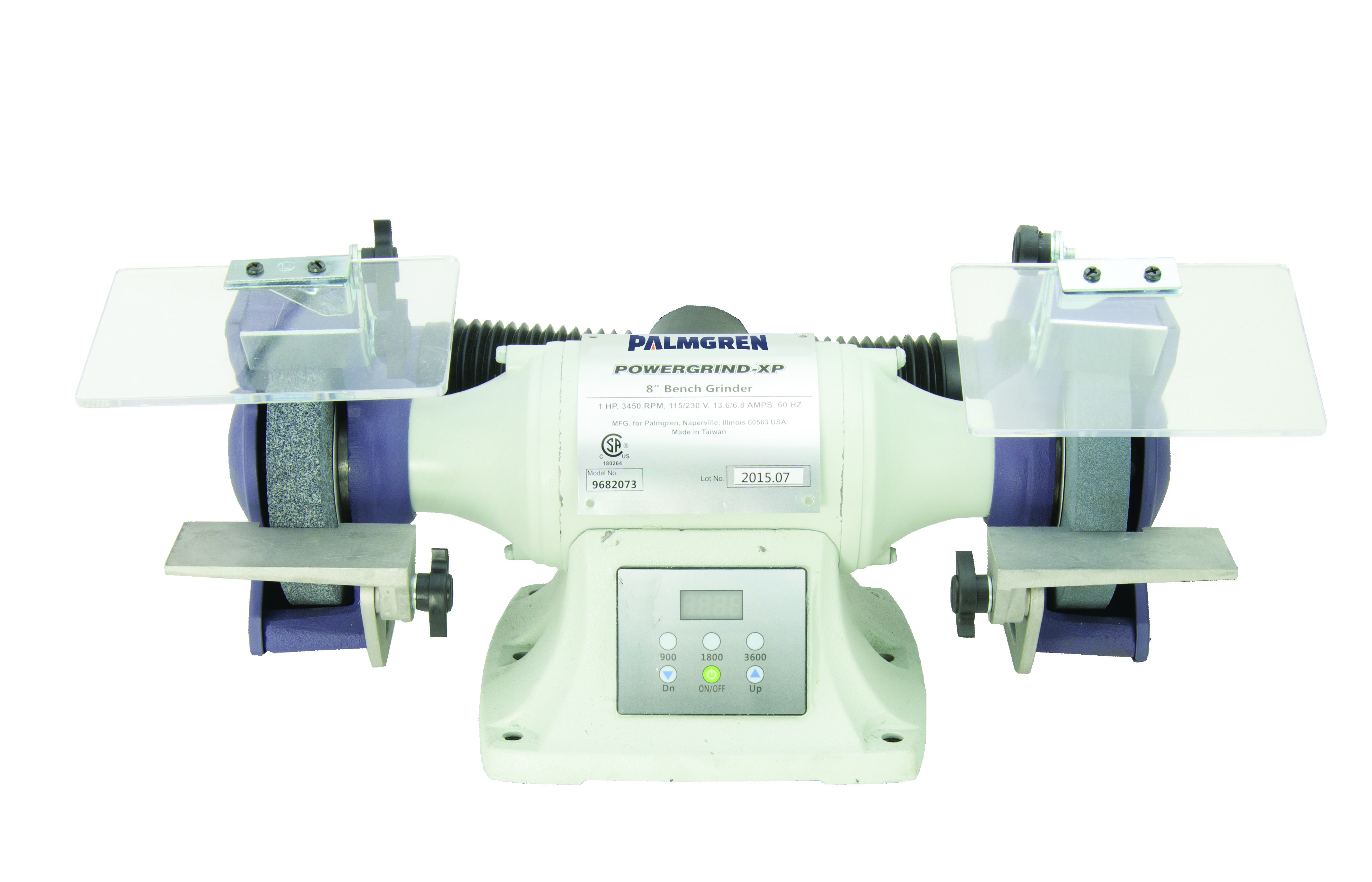

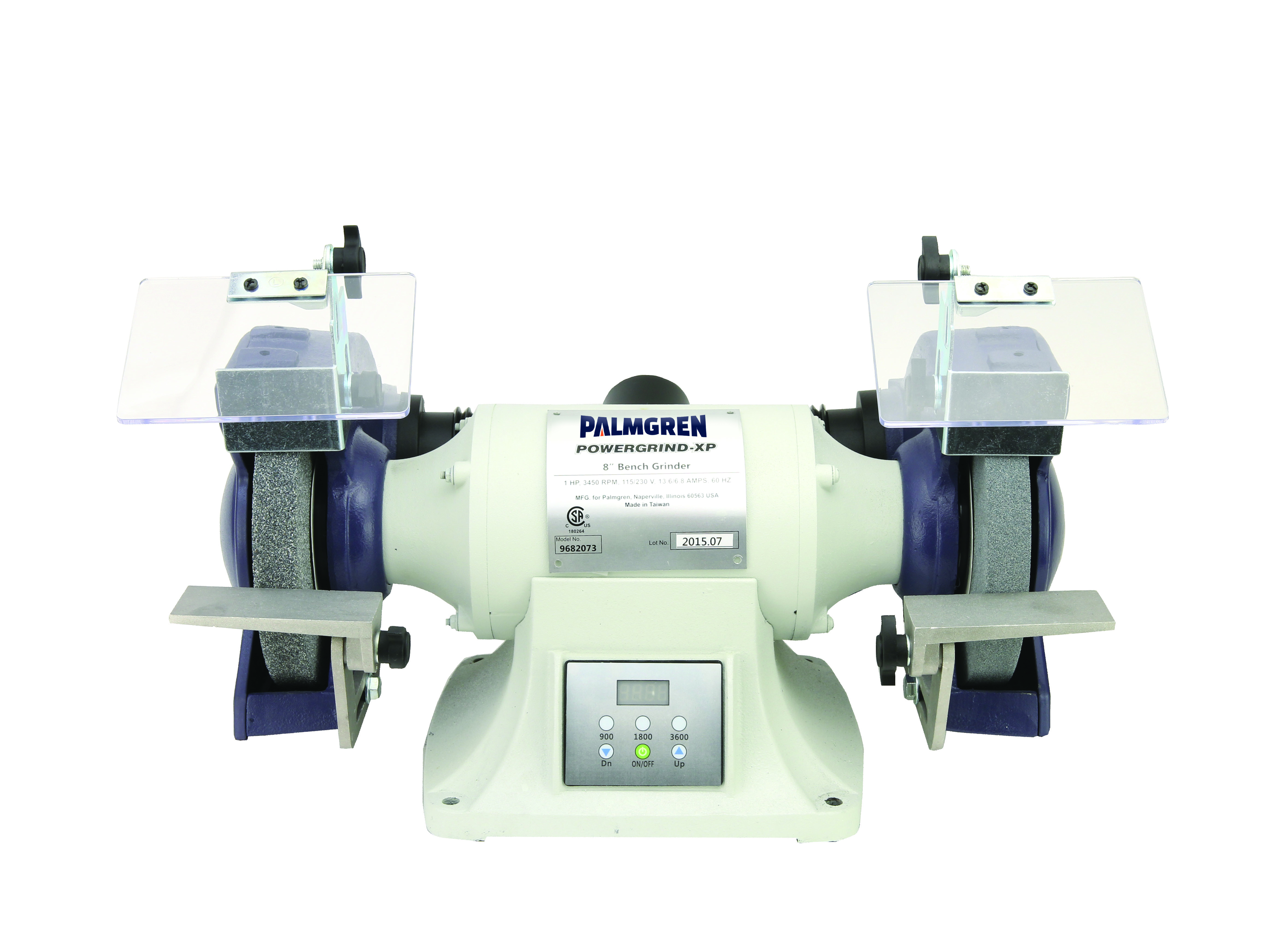

Palmgren Bench Grinders

- Palmgren offers industrial bench grinders to deliver quiet and smooth power for all cleaning, grinding, chamfering, deburring and sharpening purposes.

- They have heavy duty capacitor motors to supply the extra current which is required during the start-up process and operation under load.

- These grinders have extended wheel to wheel clearance that permits long items to be grounded safely & easily.

- The dynamically balanced rotors and sealed bearings of the units are engineered to reduce vibration and ensure smooth running.

- They come with a large adjustable tool that rests for safe angle grinding and efficient tilt.

- These grinders are supplied with adjustable safety eye shields and spark guards that can be easily positioned with hurricane bolts for additional safety.

- Palmgren bench grinders have an exclusive floor pedestal stand and a single port dust collection system with coated steel hose (in models such as Powergrind XP Series grinders).

Westward Bench Grinders

- Westward bench grinders are designed for general purpose applications requiring rotation at high speeds to create polished finish of the workpiece.

- They have built in LED worklights for a detailed view of the projects and are supplied with medium & coarse wheels (36 & 60 grit, respectively) made of aluminium oxide for excellent grinding results.

- They have adjustable tool rests and eye shields to ensure safe operation.

- Westward 1KEL8 bench grinders have a flexible LED work light with independent On/Off switch.

Working Mechanism

Bench grinders have an electric motor that supplies rotational power to the grinding wheel with the help of a pulley and belt. So when the electric motor gets started, the motor rotates at a certain speed with the help of a cone pulley and V-belt. Consequently, grinding wheels also start rotating and thus, the grinding operation is performed.

These stationary grinders mount to a workbench, and the operator uses both hands to hold the piece against the rotating belt or wheel for smoothing or forming purposes. The coarser the grit level of wheels / belts, the more material it will eliminate and the finer the grit level, the smoother the finish it will leave on the workpiece.

Frequently Asked Questions

Can you use a bench grinder without a guard?

Wheel guards deflect sparks & debris away from users, and shield & protect them against grinding wheels and abrasive cutting, which may cause serious damage if they fail or fly off.

Do bench grinders need to be bolted down?

Make sure that all grinders have guards in place and ensure that the grinder is installed to the floor / surface if the pedestal was engineered to be bolted on it. However, if bolt holes are not present, then bolting is not mandatory.

How do I choose a grinding wheel?

While choosing a grinding wheel, grinding machine horsepower should be considered. If horsepower is less than the wheel diameter, a softer grade wheel is recommended, and if horsepower is more than the wheel diameter, then choose a harder grade wheel.

Can you use a bench grinder to sharpen knives?

Bench grinders can be used to sharpen a knife. These tools have a high speed spinning wheel which can be used for trimming plastic, metallic and wooden materials.

Can I use a bench grinder to sharpen chisels?

Yes, you can sharpen your chisels on a bench grinder. Your bench grinders should have enough power and the perfect type of stone. More importantly, you should use techniques to maintain the correct bevel while preventing the overheating of the steel in your tool, which may cause softening of the cutting edge.

Why is an eye shield mounted on a bench grinder?

Many bench grinders have an embedded eye shield that will effectively protect the eyes of the operator against injuries by bits of metal and flying abrasive particles.

Why do bench grinders have 2 wheels?

Bench grinders come equipped with two wheels that can be used for numerous applications. The first wheel is mainly designed for precise sharpening, while the other wheel is ideal for rough shaping. These wheels can be conveniently swapped out for different wheel configurations as per the user's needs.

£ GBPChange Country

£ GBPChange Country